聲 Ultrasound

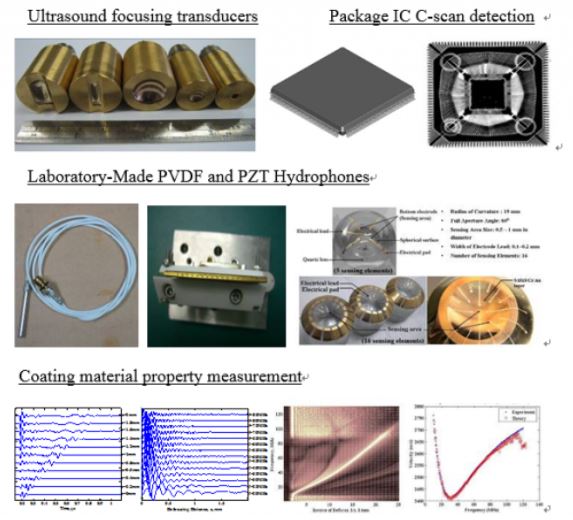

聲波感測元件與材料之非破壞檢測 Acoustic Sensing Device and Non-destructive Evaluation隨著工業的蓬勃發展,各式製程、產線陸續被開發出來。然而,為了確保產品的品質,對產品缺陷之快速、非破壞性的檢測有其必要性,從半導體晶片、金屬靶材、玻璃面版、封裝IC之缺陷裂紋的檢測到鍍層材料之機械性質量測,超音波一直是最為廣泛應用的選擇。本實驗室專精於超音波檢測方法,透過各式超音波換能器的設計與製作,並建立各式的量測整合系統,可對各式的產品作測試,也因此可達到對各式產線之快速、非破壞性檢測的需求。

Ultrasonic engineering are widely used in a variety of industry applications for the defect nondestructive evaluation and material property measurement. For different measurement requirements, such as the defect detection of silicon wafer, metal target material, LCD glass plate, electronic package IC and the coating material property measurement, we design and fabricate various ultrasound transducers with operating frequency from few MHz up to more than 100 MHz and can integrate with different measurement systems.

其他相關研究主軸

Other Researches

- 聲波感測元件與材料之非破壞檢測 (Acoustic Sensing Device and Non-destructive Evaluation)

- 半導體靶材缺陷之超音波影像 (Target Material Ultrasound Image Defect Inspection)

- 聲子晶體結構中的波傳效應 (Wave propagation in Phononic crystal structure)

- 準分子雷射微細加工 (Excimer Laser Micro Machining)

- 無光罩式斜掃描曝光系統 (Mask-less Dot Scanning Lithography System)

- 無光罩式外滾筒微影製成技術 (Mask-less Outer Cylindrical Photolithography)

- 壓電膜製作技術 (Technique of Fabricating Piezoelectric Film)

- 軟性光罩微影技術 (Soft Photo-mask Lithography)

- 平面奈米壓印 (Flat Nano-Imprinting)

- 奈米壓印 (Nano-Imprinting)

- 滾輪壓印 (Nano-Imprinting)

- 內滾筒微影製程技術 (Inner cylindrical Photolithography)

- 機械設備研發製作 (Research And Fabrication of Machines)