電 Electricity

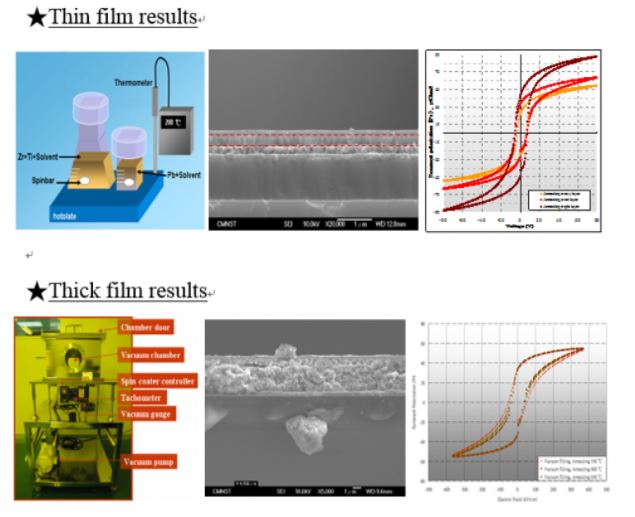

壓電膜製作技術 Technique of Fabricating Piezoelectric Film本實驗室透過改良式溶膠凝膠法針對 1~20 μm 膜厚的 PZT 壓電陶瓷膜進行材料的開發,使其具備高品質且穩定的性能。目前透過改良式溶膠凝膠法可以得到膜厚範圍介於 2.4μm ~ 12.8μm的壓電厚膜。當膜厚為12.8μm時,在最大電場625kV/cm 的狀況下,殘餘極化向量為24.48μC/cm2,而矯頑電場為 122.72 kV/cm。

We focus on the development of high-quality and stable PZT thick film around 1 to 20 μm in thickness by modified sol-gel method. Films with a thickness in the range from 2.4μm to 12.8μm can be obtained by the improved sol-gel method. When the thickness of the film is 12.8μm, the maximum remanent polarization is 24.48μC/cm and the coercive field is 122.72 kV/cm at the maximum electric field, 625kV/cm.

其他相關研究主軸

Other Researches

- 聲波感測元件與材料之非破壞檢測 (Acoustic Sensing Device and Non-destructive Evaluation)

- 半導體靶材缺陷之超音波影像 (Target Material Ultrasound Image Defect Inspection)

- 聲子晶體結構中的波傳效應 (Wave propagation in Phononic crystal structure)

- 準分子雷射微細加工 (Excimer Laser Micro Machining)

- 無光罩式斜掃描曝光系統 (Mask-less Dot Scanning Lithography System)

- 無光罩式外滾筒微影製成技術 (Mask-less Outer Cylindrical Photolithography)

- 壓電膜製作技術 (Technique of Fabricating Piezoelectric Film)

- 軟性光罩微影技術 (Soft Photo-mask Lithography)

- 平面奈米壓印 (Flat Nano-Imprinting)

- 奈米壓印 (Nano-Imprinting)

- 滾輪壓印 (Nano-Imprinting)

- 內滾筒微影製程技術 (Inner cylindrical Photolithography)

- 機械設備研發製作 (Research And Fabrication of Machines)