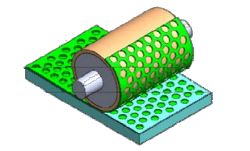

Roller

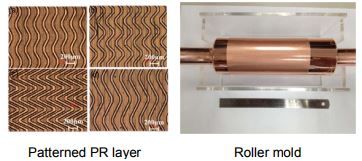

滾輪壓印 Nano-Imprinting本實驗以創新的方法利用準分子雷射加工具有高聚光效果之微透鏡陣列之光罩,藉由微透鏡陣列聚光的特性進行曲面光筆直寫微影製程,完成具有微米尺寸波浪結構的無縫滾筒模仁。其無縫滾筒模仁可經由UV滾印製程完整的轉移至PET基板,完成微米尺寸波浪結構的複製。

This investigation presents an innovative method for directly fabricating roller mold with wave microstructure based on beam pen lithography. The major steps in the fabrication process include the pneumatic air-flow coating of a thin PR layer, a continuous UV exposure by x-axis stage move and mask with microlens arrays. chemical etching and electro-polishing to improved surface roughness. In this work, we have successfully fabricated the different wave microstructure on the surface of metal roller which is the seamless roller mold.

其他相關研究主軸

Other Researches

- 聲波感測元件與材料之非破壞檢測 (Acoustic Sensing Device and Non-destructive Evaluation)

- 半導體靶材缺陷之超音波影像 (Target Material Ultrasound Image Defect Inspection)

- 聲子晶體結構中的波傳效應 (Wave propagation in Phononic crystal structure)

- 準分子雷射微細加工 (Excimer Laser Micro Machining)

- 無光罩式斜掃描曝光系統 (Mask-less Dot Scanning Lithography System)

- 無光罩式外滾筒微影製成技術 (Mask-less Outer Cylindrical Photolithography)

- 壓電膜製作技術 (Technique of Fabricating Piezoelectric Film)

- 軟性光罩微影技術 (Soft Photo-mask Lithography)

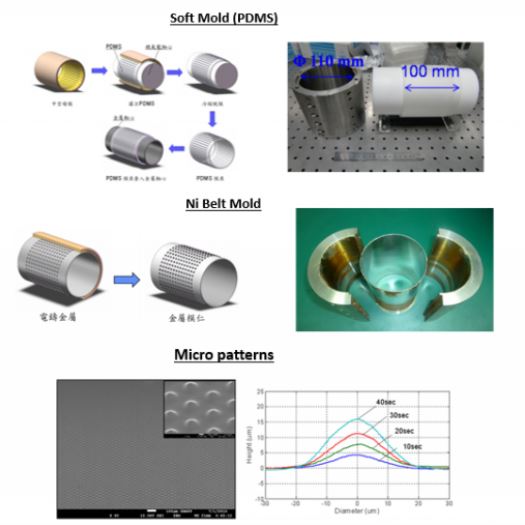

- 平面奈米壓印 (Flat Nano-Imprinting)

- 奈米壓印 (Nano-Imprinting)

- 滾輪壓印 (Nano-Imprinting)

- 內滾筒微影製程技術 (Inner cylindrical Photolithography)

- 機械設備研發製作 (Research And Fabrication of Machines)