光 Light

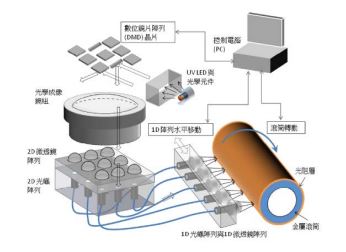

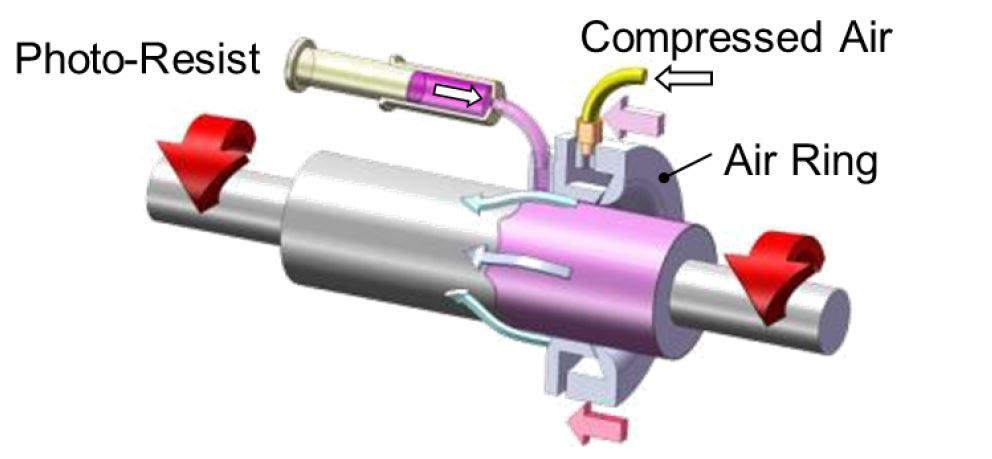

無光罩式外滾筒微影製成技術 Mask-less Outer Cylindrical Photolithography光源部分如下圖,有三項硬體:UV-LED光學元件、數位鏡片陣列與光學成像鏡組;三者構成一完整的「數位光學投影」系統。另外利用光纖陣列,其左端接收來自數位光學投影系統的UV光,且排列成二維陣列,右端為出光面,且排列成一維陣列,透過雷射拖曳加工法在兩端加工特定形貌微透鏡陣列。撰寫程式控制數位鏡片陣列每一個畫素的亮暗,並搭配雙軸位移平台和旋轉伺服馬達,在金屬滾筒上完成非週期性結構,達到無光罩式微影製程技術。

The light source is show as follow figure. The Digital Light Process(DLP) include three device, UV-LED optical components、Digital Micro-mirror Device(DMD) and projection lens. Using the fiber array, which the purpose of the left hand side(LHD) is to collect the UV light from DLP, and arrange the LHD as 2D array. In the right hand side(RHS) of the fiber array is to focus the UV light to do the lithography on the roller, and arrange the RHS as 1D array. Using the Laser Dragging Process to manufacture the design surface profile micro-lens on the both side. Control each pixel of the DMD、2-axis stages and servomotor to manufacture aperiodic structure on the metal roller to achieve the mask-less lithography technique.

其他相關研究主軸

Other Researches

- 聲波感測元件與材料之非破壞檢測 (Acoustic Sensing Device and Non-destructive Evaluation)

- 半導體靶材缺陷之超音波影像 (Target Material Ultrasound Image Defect Inspection)

- 聲子晶體結構中的波傳效應 (Wave propagation in Phononic crystal structure)

- 準分子雷射微細加工 (Excimer Laser Micro Machining)

- 無光罩式斜掃描曝光系統 (Mask-less Dot Scanning Lithography System)

- 無光罩式外滾筒微影製成技術 (Mask-less Outer Cylindrical Photolithography)

- 壓電膜製作技術 (Technique of Fabricating Piezoelectric Film)

- 軟性光罩微影技術 (Soft Photo-mask Lithography)

- 平面奈米壓印 (Flat Nano-Imprinting)

- 奈米壓印 (Nano-Imprinting)

- 滾輪壓印 (Nano-Imprinting)

- 內滾筒微影製程技術 (Inner cylindrical Photolithography)

- 機械設備研發製作 (Research And Fabrication of Machines)